Custom Acoustic Guitar: Deep Discussion from Side Bending of Body

Why Bending of Side of Guitar Body is Critical During Custom Acoustic Guitar

To custom acoustic guitar, we always firstly pay attention to the body.

Many may think that the shape of top and back determines the shape of body. That is true. But there are at least two aspects need to be considered when design the body. One is the design has to follow the principle of sound production. Another is the practicability of side bending. The two aspects must be meet at the same time, otherwise, it is not possible to build a satisfying body.

This is the main reason why bending of side is so critical during building of a guitar.

We are glad to share our thoughts here to help a general idea about the body design when customize acoustic guitar. In this article, we will try to explain why not all bending design is applicable through explanation of the bending ability of various wood, the positions of the side that need to be bent, etc. Thus, all of us may understand the point better. Most importantly, we hope this can give some designers a general idea when design and custom acoustic guitar body.

The Easiest and Hardest Tone Wood for Bending

Different wood has different density of grain. Therefore, simplicity of bending of various tonewood is various. This is one reason why some designation of side cannot be bent.

Indian Rosewood is one of the most common tone woods for guitar building. The wood is pliable because of the resins. Besides, plain maple is also easy to bend.

Mahogany and walnut have a stronger resistance of bending; thus, it needs to pay close attention to heating temperature, etc. for bending. Once the conditions are not right, the bending will be a disaster.

Figured woods are the most difficult to bend like figured curly koa, curly maple and figured rosewood.

When custom acoustic guitar body, the difficulty of bending based on the character of the tone wood must be carefully considered. For electric body, cause the shaping of the body mainly involves CNC work, it may easier to handle the wood.

The Positions of Bending

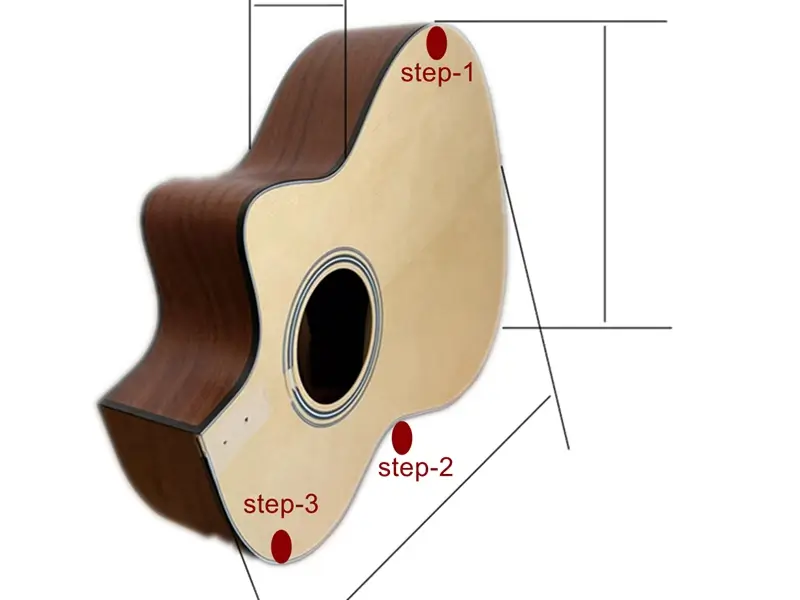

In the imagination of many people, the bending of the guitar side is so simple. But actually, it is not. As indicated by the shape of the acoustic guitar body, there are three bending positions as following diagram. And as our experience, they should be bent step by step.

The lower part of body should be bent firstly (step-1). Then, the waist (step-2). Final bending is on the upper part of the body (step-3).

Besides, don’t forget that there is heating and watering during the bending. But that doesn’t mean that the wood is boiled. The water just keeps the wood wet when it touches the heated iron. Thus, inside the wood there is the steam. The steam makes the fibers flexible so they’ll stretch (outside fibers) and compress (inside fibers) evenly. After cooling and drying, the curve of the wood will remain permanently.

Custom Acoustic Guitar with Proper Design

Now we can see the complexity of bending side of acoustic guitar body.

However, it doesn’t mean that there is a strict limitation to custom acoustic guitars. Actually, in our experience, the most of the design is sensible for the customization.

Besides, we will inspect the requirement very carefully at the beginning. And the designation of shape and dimension, even the each of the angle will be significantly considered. Therefore, there is a procedure of discussion and confirmation before the order.

Just keep in mind that the side of the guitar body is one of the critical aspects of guitar customization. If any needs, please feel free to CONSULT US.